A roller shell is a critical component in the pelletizing process used in various industries, including feed mills and wood pellet plants. It serves as the outer surface of the roller assembly in pellet mills, working in conjunction with the ring die to compress and shape the raw materials into pellets

Sprint Drives supplies top-quality Roller shells to different Industries, including Feed and Wood industries. Our roller shells are trusted by leading feed groups and pellet producers worldwide.

Customized Roller Shell According To Different Request

We supply roller shells according to the client's special request

Material | Hardness | Suitable For |

20MnCr5 | HRC58-60 | Feed Pellet & Wood Pellet |

100Cr6 | HRC58-61 | Wood Pellet |

Durable Pellet Mill Roller Shell Come From Advanced Equipment And Processes

From raw material monitoring to finished product delivery, every step of the process is meticulously controlled to ensure our products' highest quality and precision.

Advanced Equipment And Processing

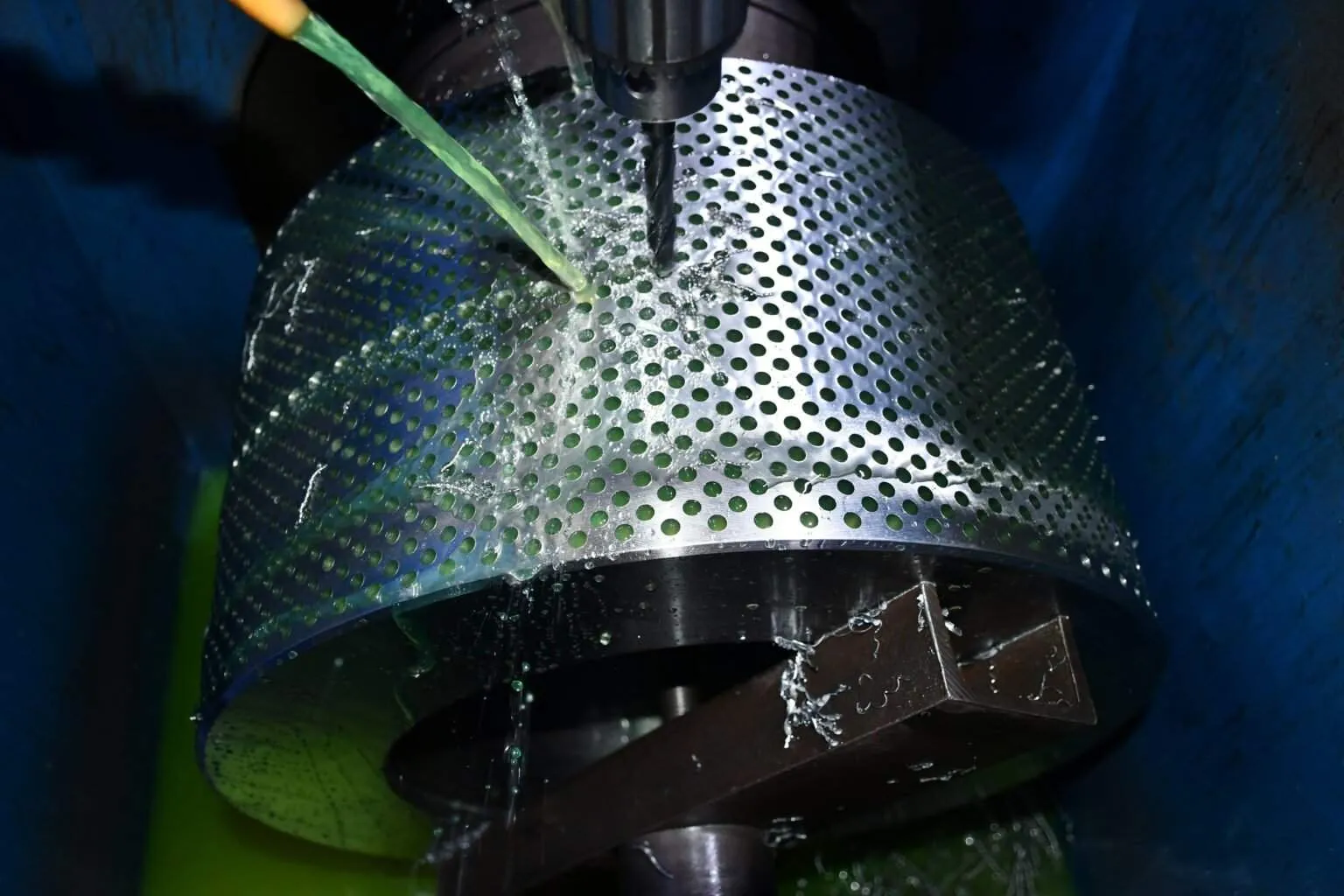

FULL AUTOMATIC PROCESSING MACHINE: We use full automatic equipment to process corrugated and dimpled roller shells, ensure the precise size and smoothness of the hole

HEAT TREATMENT: The largest heat treatment furnace in the world to meet mass roller shell processing and ensure delivery in time Full-automatic vacuum heat treatment furnace combined with advanced quenching processing of ring die to make sure the hardness to HRC52-55

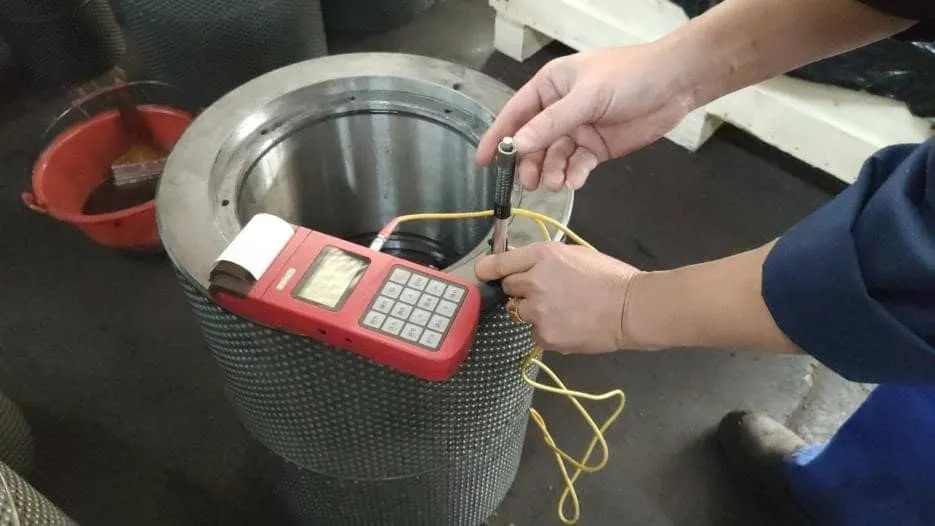

Professional Testing For Guaranteed Quality

Sprint Drives provides an inspection report for each die leaving the factory

Inspection Report | Hardness Check | Finished Product |

Product Gallery